The two projects I am currently working on are at the same stage of construction. As neither have purpose-built windscreens (for different reasons) I will have to make some.

It's not a difficult job, and indeed it's surprising how many kits these days still require you to make your own windscreens (the next two kits I will be making are from PST and Hunor and both require me to do so). So here's my procedure for doing this (I do not claim it's the best way, just the way that works for me)...

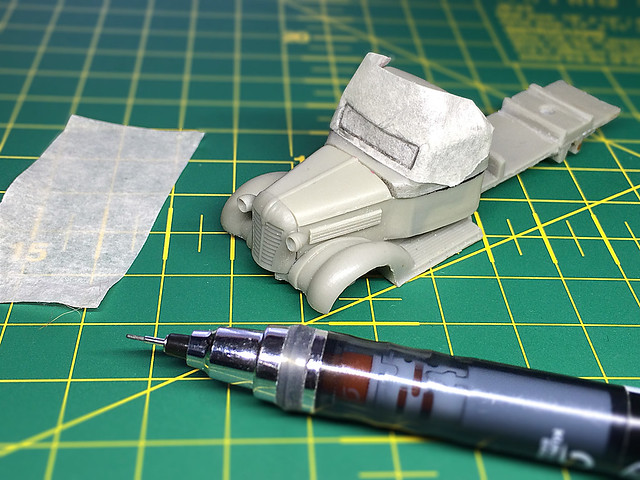

1. Create templates for your windows.

I begin by masking over the vehicle's empty window spaces. Then I take a sharp pencil or technical pencil and carefully draw around the window...

I press very gently and get the point of the pencil lead just inside the lip of the window. I use the shape of the window itself to guide my pencil around the edge so I end up with a drawing of the exact contour of the inside of the window.

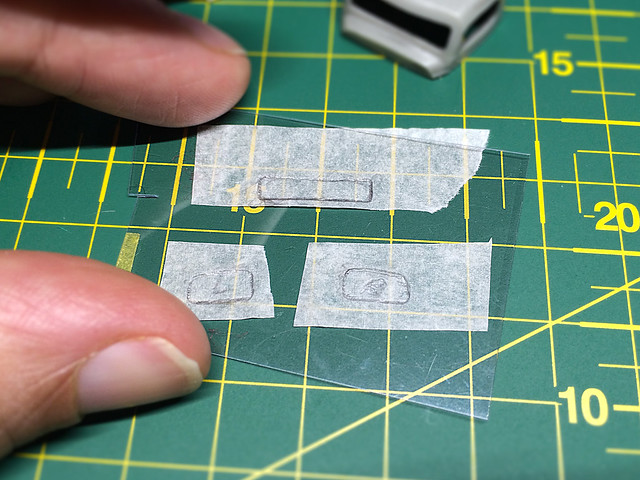

2. I transfer the contour template onto transparent plastic.

Then I just stick the masking tape with the template on it to a flat surface, lay some transparent plastic over it and trace the outline using an indelible pen...

Not the best photos I've ever taken, but then transparent plastic isn't the easiest thing to photograph. My drawings are a bit shaky, but I will cutting generously and sanding the window edges to fit. It's a bit time-consuming, but the best way to ensure and exact and snug fit, especially with resin models where straight lines ain't so straight sometimes.

3. Fitting...Carefully now!

I'll be honest, it took a couple of goes to cut the correct shapes - or nearest thing to them - and then some very careful filing using my trusty Squadron Premium Sanding Stick. These sanding sticks are excellent and come in a variety of 'grits' right down to a very fine. They do make the difference.

Pacer's Formula '560' is my go to glue for canopies and windscreens, it dries a crystal clear...

Hard to tell but the windscreens have been fitted! I finished them off by painting on a layer of Johnson's Klear (now Pledge Multi-Surface Wax) which not only makes the 'windows' shine but clears up any light scratches and helps to stick the windshield in place securely.

Conclusion

Making your own windscreens is a bit of a black art. Sometimes you get a perfect fit first time, but then sometimes one windscreen can be an absolute bitch and needs recutting a couple of times. You just keep going until you are happy.

Things like a good canopy glue and using Klear are a big help, but no matter how experienced you are things can go wrong. Even when I thought I had made a good job I have looked at my work the next day and found a fingerprint or spec of dust or scratch on the inside of the glass. Boy, is that frustrating.

One thing is that I no longer buy expensive sheets of transparent 'modelling' plastic. Two reasons for this, aside from it being costly I found - no matter how I tried - keeping the sheet pristine and unscratched is neigh on impossible. Far better to use clear plastic from blister packaging or food packs - it's cheaper and you can always guarantee it's unscratched when you begin.

Well - that's my thinking anyway.

No comments:

Post a Comment